Steel castings shall be used after heat treatment. The strength, especially plasticity and toughness of steel castings are greatly reduced due to the existence of porosity, cracks, shrinkage and porosity, coarse grains, uneven structure and residual internal stress in the as cast steel castings.

In order to refine grain size, uniform structure and eliminate internal stress, steel castings must be normalized or annealed. The normalized steel has higher mechanical properties and lower cost than annealed steel, so it is widely used. However, normalizing treatment can cause larger internal stress than annealing, so it is only suitable for steel castings with carbon content less than 0.35%. Because low carbon steel casting has good plasticity, it is not easy to crack when cooling. In order to reduce the internal stress, steel castings should be tempered at high temperature after normalizing. For the steel castings with carbon content ≥ 0.35%, complex structure and easy to crack, only annealing treatment can be carried out. Steel castings should not be quenched, otherwise they are easy to crack.

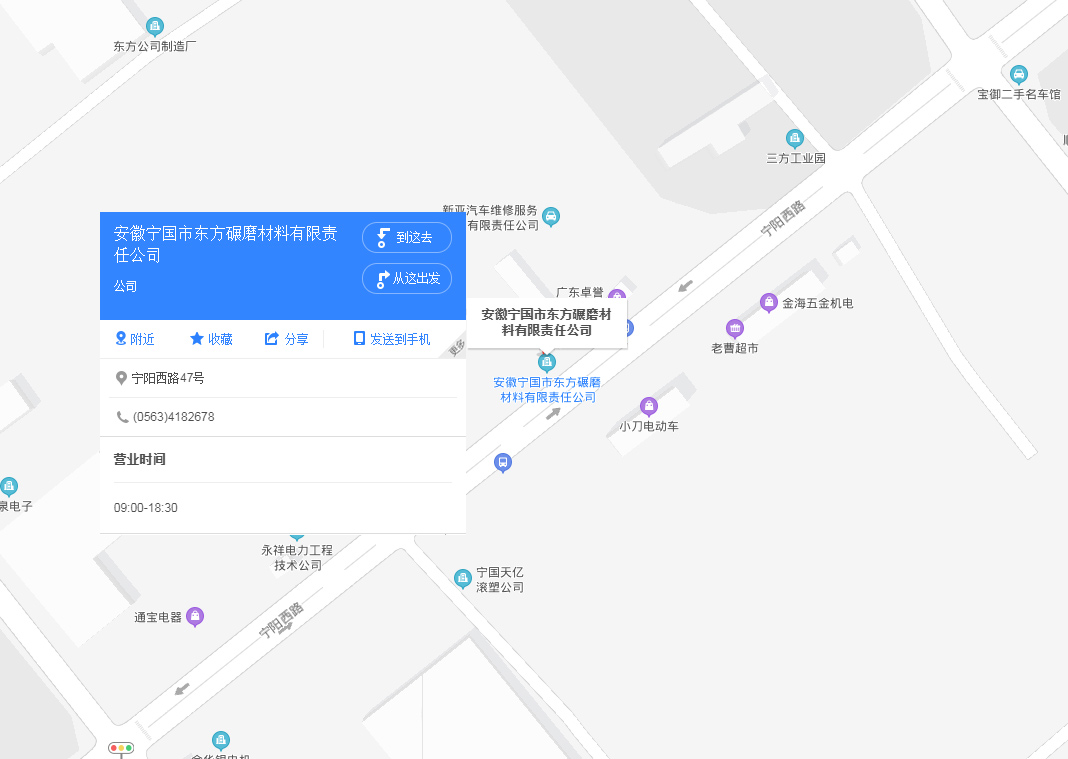

Address: No. 47 Ningyang West Road, Ningguo City, Anhui Province

Phone: +86 0563-4184901

Fax:+86 0563-4182677

Email: web@ng-df.com

Mobile

official account