For a long time, low chromium and forged steel balls have been widely used as abrasives in cement industry, thermal power plant, especially in iron ore and nonferrous metal mining and processing industries. Some domestic steel ball manufacturers have done a lot of work to replace low chromium balls and forged balls with high chromium cast balls. However, due to poor product quality and poor wear resistance, sometimes a large number of damages occur, bringing economic benefits to users. It cannot change the status quo.

The economic benefits of mining sphere are analyzed from several aspects (taking iron ore as an example)

Most mines generally use low chromium ball, its price is about 6000 yuan / ton, and the consumption of grinding body is about 3kg per ton of concentrate powder. When zqcr 10 ordinary high chromium ball is used in our plant, the average price is 8000 yuan / ton (excluding freight and packing fee, the same below), and the consumption of concentrate powder is 1.5kg/t. Using high chromium ball instead of low chromium ball can greatly reduce the actual consumption per unit year of steel ball, so as to save steel ball as follows. Direct benefits, lower freight costs and increased Taiwan production will also yield greater benefits.

1。 Reduce the purchase cost caused by wear: the original use of low chromium ball mill 3kg, the price is 6000 yuan / ton, the total value of 300 tons of low chromium ball mill 100000 tons of concentrate powder 1.8 million yuan; now use high chromium ball. The wear resistance is 1.5kg, the price is 8000 yuan / ton, the production of 100000 tons of concentrate powder needs 150 tons of high chromium ball, with a total value of 1.2 million yuan. Two yuan and one yuan, saving 600000 yuan. At the same time, due to the reduction of purchase quantity, a lot of freight has been saved.

2。 From the perspective of customer workshop, the consumption cost of concentrate powder per ton is 8000 yuan / ton * 1.5kg/ton by using zqcr10 ordinary high chromium ball? Concentrate powder = 12 yuan, using zqcr2 high chromium ball reflects the consumption cost of concentrate ball is 6000 yuan / ton * 3kg / ton? Concentrate ball = 18 yuan, the consumption cost of each ton of concentrate powder is reduced by 6 yuan. The production of 100000 tons of concentrate powder can save 600000 yuan with considerable economic benefits.

3。 Because carbides are dispersed in the matrix structure of high chromium ball, the content of (Cr, c) 7C 3 carbide is high, the wear resistance is good, the wear resistance is low, and the grinding efficiency is high. It not only improves the fineness of the concentrate to a certain extent, but also increases the output of the concentrate when feeding, and ensures and improves the quality of the concentrate powder. At the same time, the labor intensity of workers is prolonged.

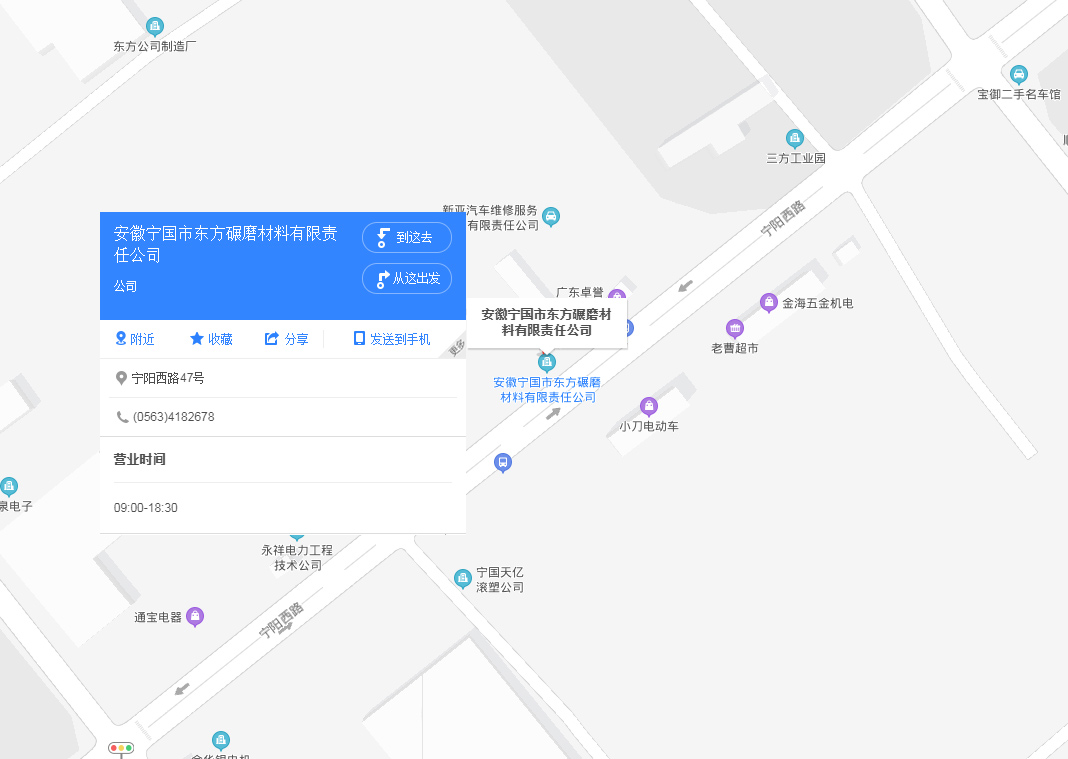

Address: No.47, Ningyang West Road, Ningguo City, Anhui Province

Sales Department:0563-4184901 web@ng-df.com

Manager of international trade department: Xiao Xingxian 18956398241 jeff@ng-df.com

Tel: 0563-4184866

Fax: 0563-4182677

Mobile

official account